Copper Foil & Copper Strip slitting

2024-04-15

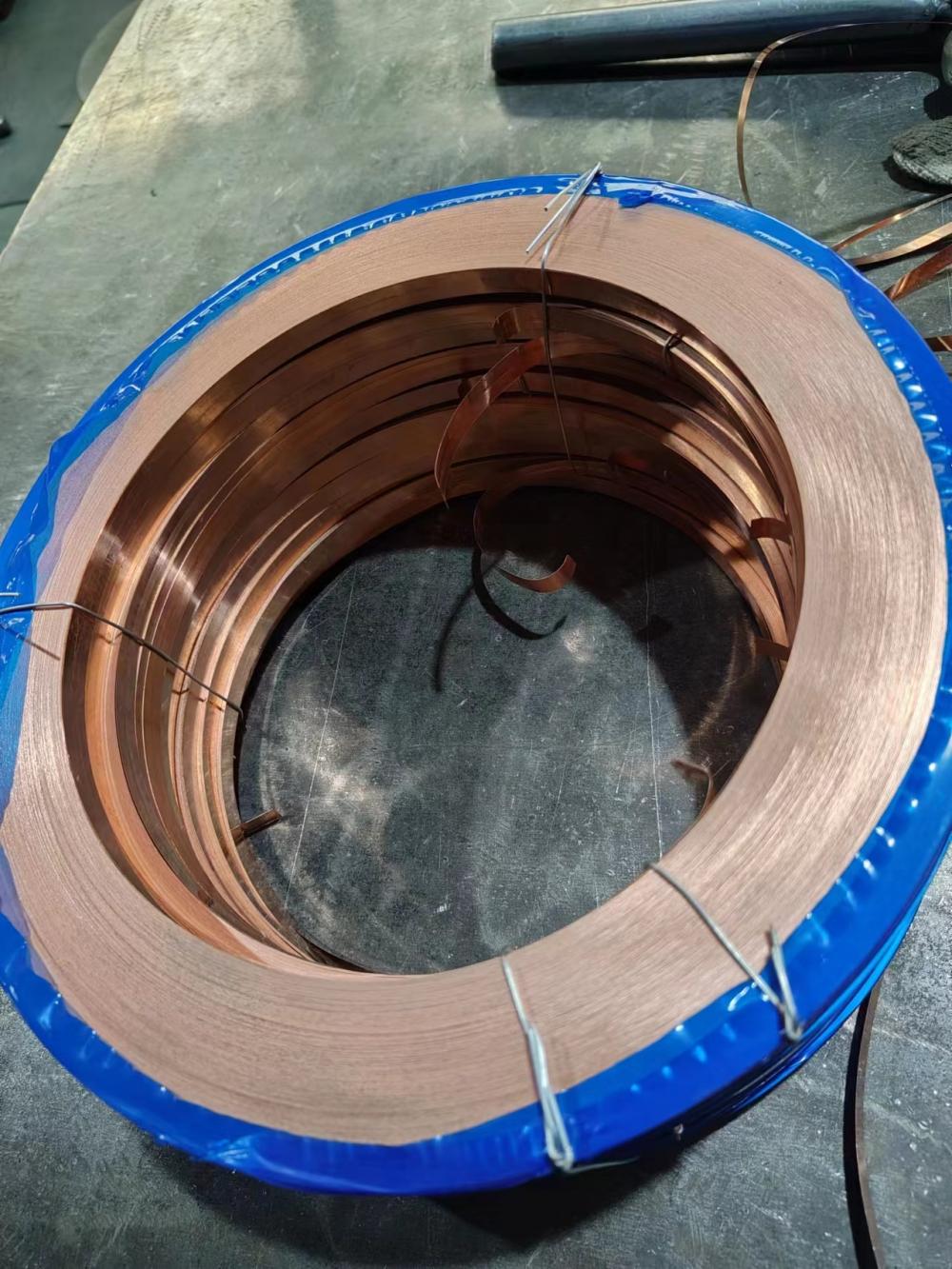

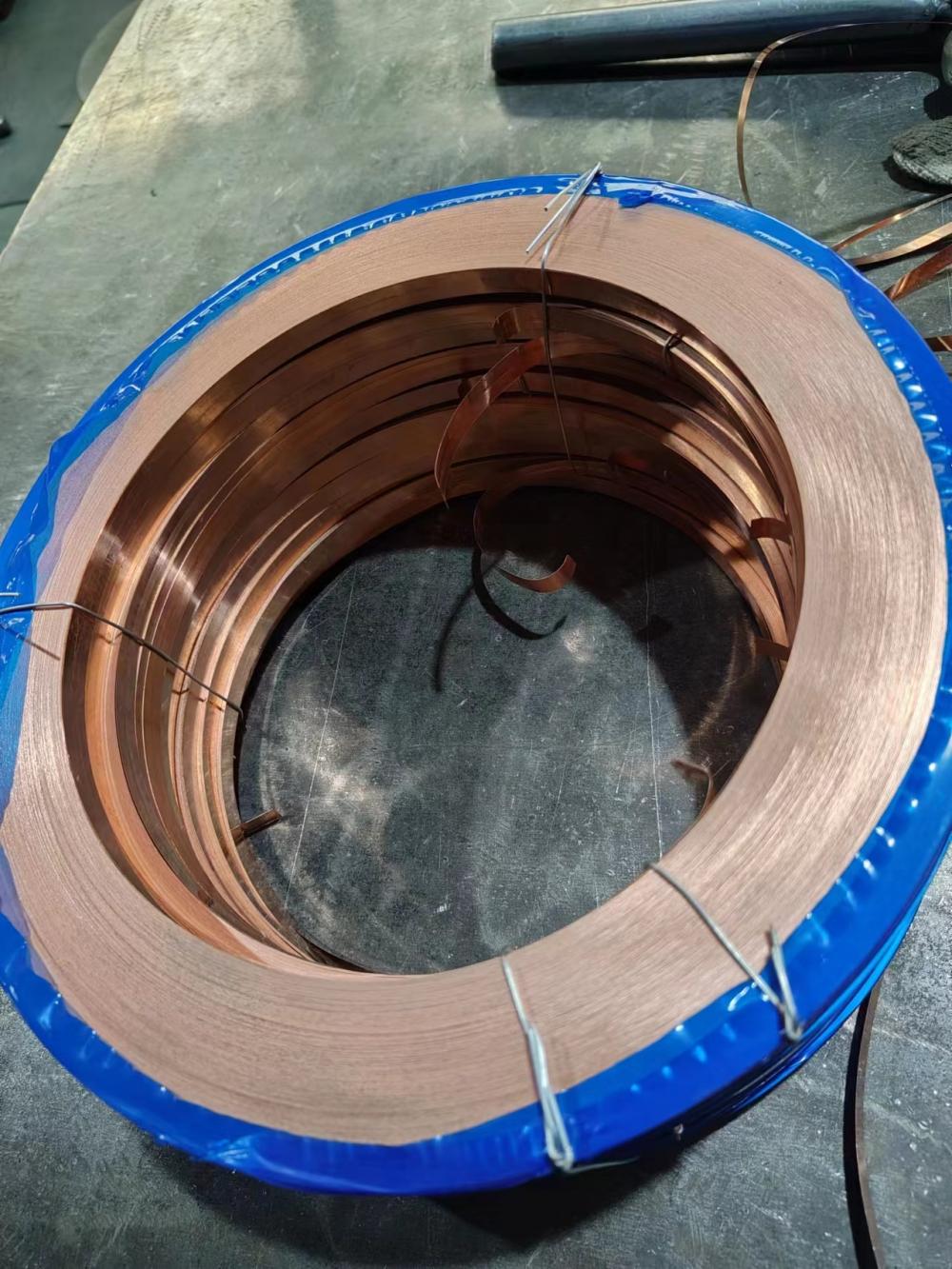

Copper foil and copper strip are essential materials in various industries, including electronics, construction, and automotive. These materials are used for a wide range of applications, such as circuit boards, electrical wiring, roofing, and heat exchangers. In order to meet the specific requirements of different applications, copper foil and copper strip need to be precisely cut into the desired widths and lengths. This process is known as slitting. Slitting is a manufacturing process that involves cutting a large roll of material into narrower strips. In the case of copper foil and copper strip, slitting is typically done using specialized equipment that can handle the high tensile strength of these materials. The slitting process is crucial for ensuring that the copper foil and strip meet the precise specifications required for their intended use. There are several factors that need to be considered when slitting copper foil and copper strip. These include the thickness of the material, the width of the strips required, and the quality of the edges. It is important to use high-quality slitting equipment that can produce clean, straight cuts without damaging the material. Additionally, the slitting process needs to be carefully monitored to ensure that the dimensions of the strips are consistent and accurate.

Copper foil and copper strip are essential materials in various industries, including electronics, construction, and automotive. These materials are used for a wide range of applications, such as circuit boards, electrical wiring, roofing, and heat exchangers. In order to meet the specific requirements of different applications, copper foil and copper strip need to be precisely cut into the desired widths and lengths. This process is known as slitting. Slitting is a manufacturing process that involves cutting a large roll of material into narrower strips. In the case of copper foil and copper strip, slitting is typically done using specialized equipment that can handle the high tensile strength of these materials. The slitting process is crucial for ensuring that the copper foil and strip meet the precise specifications required for their intended use. There are several factors that need to be considered when slitting copper foil and copper strip. These include the thickness of the material, the width of the strips required, and the quality of the edges. It is important to use high-quality slitting equipment that can produce clean, straight cuts without damaging the material. Additionally, the slitting process needs to be carefully monitored to ensure that the dimensions of the strips are consistent and accurate.  Copper foil and copper strip slitting can be done using a variety of methods, including rotary slitting, razor slitting, and crush cutting. Each method has its own advantages and disadvantages, depending on the specific requirements of the application. For example, rotary slitting is commonly used for high-volume production of narrow strips, while crush cutting is preferred for thicker materials that are more difficult to cut. In addition to the slitting process itself, it is also important to consider the handling and packaging of the copper foil and copper strip after they have been cut. Proper handling is essential to prevent damage to the material, while careful packaging ensures that the strips remain clean and free from contaminants. Overall, copper foil and copper strip slitting is a critical step in the manufacturing process of these materials. By using high-quality equipment and closely monitoring the slitting process, manufacturers can ensure that the copper foil and strip meet the precise specifications required for their intended applications.

Copper foil and copper strip slitting can be done using a variety of methods, including rotary slitting, razor slitting, and crush cutting. Each method has its own advantages and disadvantages, depending on the specific requirements of the application. For example, rotary slitting is commonly used for high-volume production of narrow strips, while crush cutting is preferred for thicker materials that are more difficult to cut. In addition to the slitting process itself, it is also important to consider the handling and packaging of the copper foil and copper strip after they have been cut. Proper handling is essential to prevent damage to the material, while careful packaging ensures that the strips remain clean and free from contaminants. Overall, copper foil and copper strip slitting is a critical step in the manufacturing process of these materials. By using high-quality equipment and closely monitoring the slitting process, manufacturers can ensure that the copper foil and strip meet the precise specifications required for their intended applications.

Copper foil and copper strip are essential materials in various industries, including electronics, construction, and automotive. These materials are used for a wide range of applications, such as circuit boards, electrical wiring, roofing, and heat exchangers. In order to meet the specific requirements of different applications, copper foil and copper strip need to be precisely cut into the desired widths and lengths. This process is known as slitting.

Copper foil and copper strip are essential materials in various industries, including electronics, construction, and automotive. These materials are used for a wide range of applications, such as circuit boards, electrical wiring, roofing, and heat exchangers. In order to meet the specific requirements of different applications, copper foil and copper strip need to be precisely cut into the desired widths and lengths. This process is known as slitting.